Thompson Appalachian’s mission is full forest utilization with zero waste. With this goal, we produce a variety of forest products ranging from high-quality grade hardwood lumber for furniture, flooring and millwork packages to high volumes of industrial products for the railroad and packaging industries to biofuel stock for energy markets. Our team is committed to high-quality manufacturing and timely delivery to any marketplace around the world.

Lumber

Rooted in Quality

Thompson Appalachian produces high-quality, green and kiln-dried hardwood lumber in a variety of species, thicknesses, and grades. As an NHLA-certified manufacturer, we are committed to precision manufacturing and handling of our lumber products throughout the process. This ensures consistent performance and optimum yields for our customers.

Our species include Ash, Cherry, Cypress, Hard Maple, Hickory, Poplar, Red Oak, Walnut, and White Oak. We specialize in cutting and drying 5/4, 6/4, and 8/4 thickness in all species. Please contact our Sales Team for additional information.

Ash

Ash has nearly white sapwood, and the heartwood ranges from grey-brown to a pale yellow with brown streaks. The wood is usually straight-grained, although different grain patterns can emerge that enhance Ash’s unique beauty. The species has a coarse uniform texture and is relatively lightweight for its strength and high shock resistance. Great for nailing, screwing, and gluing, Ash has excellent flexibility and bending qualities. Ash also takes stain and polishing well.

Thickness:

4/4 – 16/4

Grades:

FAS/1F, 1COMMON, 2COMMON

Sawing Styles:

Plain Sawn, Quarter Sawn,

Rift Sawn

Uses:

Furniture, Doors, Architectural Interiors, Joinery, Moldings, Kitchen Cabinets, Sporting Goods and Turnery

Ash in Use

Poplar

Thickness:

4/4 – 16/4

Grades:

FAS/1F, 1COMMON, 2COMMON

Sawing Styles:

Plain Sawn

Uses:

Furniture, Doors, Millwork, Moldings, Baskets, Turnery, Interior Trim and Millwork, Cabinetry and Exterior Trim

Poplar in Use

Red Oak

Red Oak is a mostly straight-grained hard and heavy wood that gets its name because of the color of its autumn leaves. The heartwood ranges from pinkish-reddish brown in color, and sapwood white to light brown. Quarter sawn Red Oak boasts an attractive figure, and rift sawn Red Oak has a distinct pinstripe.

Thickness:

4/4 – 16/4

Grades:

FAS/1F, 1COMMON, 2COMMON

Sawing Styles:

Plain Sawn, Live Sawn, Quarter Sawn, Rift Sawn

Uses:

Flooring, Furniture, Architectural Interiors, Internal Moldings and Cabinetry

Red Oak in Use

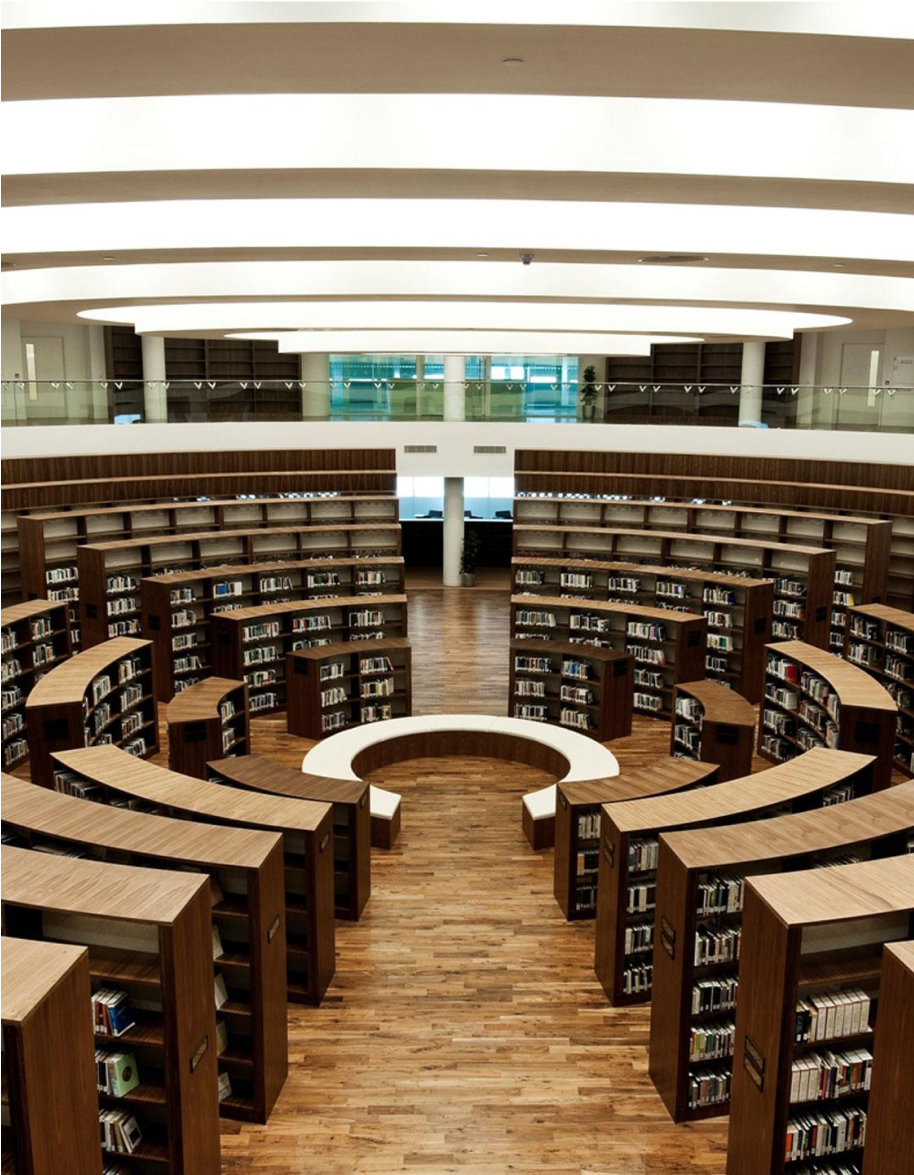

White Oak

White Oak is a mostly straight-grained hard and heavy wood. The heartwood is light to dark brown, and the sapwood is lightly colored. It has medium to coarse texture, with long rays. Quarter sawn White Oak has a more prominent figure than Red Oak. Rift sawn White boasts a distinct pinstripe. White Oak is especially popular where strength and durability are required and is one of North America’s leading hardwood species.

Thickness:

4/4 – 16/4

Grades:

FAS/1F, 1COMMON, 2COMMON

Sawing Styles:

Plain Sawn, Live Sawn, Quarter Sawn, Rift Sawn

Uses:

Flooring, Furniture, Exterior Joinery, Architectural Joinery, Moldings, Doors, and Cabinetry

White Oak in Use

Walnut

Walnut sapwood is creamy white, and the heartwood can vary from light to chocolate or purplish brown. Walnut is typically steamed before kiln drying to darken the color of the sapwood. The wood is generally straight grained with coarse texture and can range from plain to highly figured. Although it is dense, Walnut generally machines and glues without difficulty.

Thickness:

4/4 – 16/4

Grades:

FAS/1F, 1COMMON, 2COMMON

Sawing Styles:

Plain Sawn

Uses:

Furniture, Cabinetry, Moldings, Turnery, Carving, Flooring, Musical Instruments and Boat Interiors